Rachael DiSciullo needed a new stuffed house wren. The taxidermy model she had been using for her dissertation research on the birds’ mating habits was worn out.

“The wrens can be rather aggressive,” explained DiSciullo, a doctoral student in the School of Biological Sciences. She is carrying out her research under the direction of Drs. Scott Sakaluk and Charles Thompson, whose lab has been conducting a running study on house wrens since 1980.

DiSciullo was looking for an alternative to a dead wren and if possible, a covey of models, for a study she was conducting in summer 2021. She planned to place the imitation male wrens at birdhouses in a nature preserve near Lexington, and then play birdsongs she had recorded and altered from her sample population to study what components of male song are attractive to females.

“(House) wrens aren’t threatened in any way, but it’s better to not use real animals from a museum collection,” she said. “The other thing is there’s a statistical problem called pseudoreplication. When you’re publishing research, reviewers might be concerned that if there is just one model, there’s something weird about this particular bird that the individuals are reacting to, rather than just using it as kind of a stimulus itself.”

Sakaluk had read about other researchers using 3D-printed birds in their studies. That’s when DiSciullo turned to Milner Library, which offers free 3D printing services to students, faculty, and staff at Illinois State. The library was able to find a pre-existing 3D model of a wren and produced five for the lab.

“I think these are great,” DiSciullo said. “The master’s student (Madi Rittinger M.S. ’21) who painted them did a great job too.”

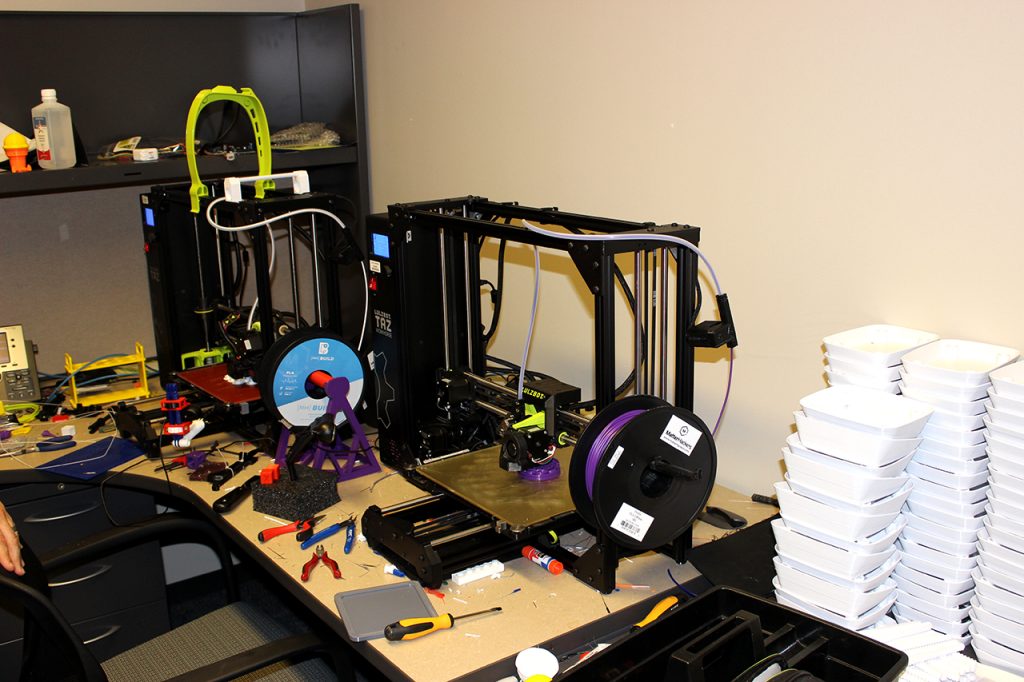

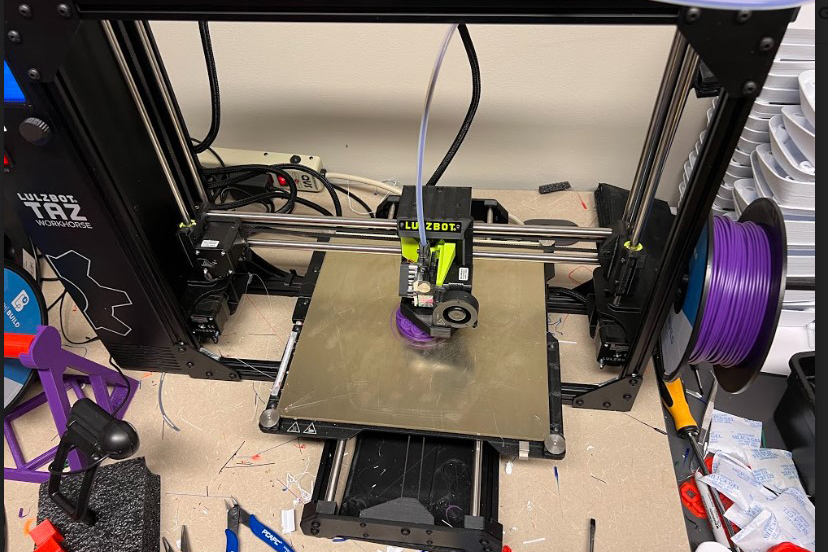

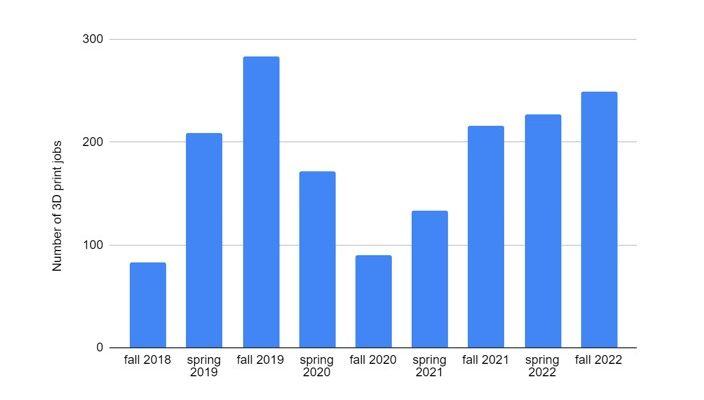

Since purchasing a 3D printer in 2018, the library has completed 1,662 projects (as of mid-October) and is on pace to blow past the previous semester high (see chart). Three printers have been added over the last three years, while the original serves as a backup.

“We’re planning to retire that one,” said Paul Unsbee ’04, M.S. ’15, the library’s director of IT services. “But we have had such a massive increase in engagement this semester that we’re milking it for everything it’s got.”

Unlike many universities with 3D printers, Milner Library staff oversees the printing themselves, and free of charge. “We decided to do that because very few students have the time or the interest to know how a 3D printer functions, and we have classes that teach you that on campus if you want to learn that,” Unsbee said.

The person behind the machines is library digital media specialist Steve Koehler ’06, an alum of what is now the Creative Technologies Program.

“This is very much in my wheelhouse,” Koehler said. “It’s creative, it’s technology, and I get to make new things all the time. I just love it.”

With the assistance of student worker Jay Yonan, Koehler processes the requests and sets the parameters for each printing job. Then the printers go to work. Projects take an average of five hours to print but can last more than a day. Once printing is complete, Koehler removes the support brackets, which can be a tedious task.

The submitted projects range from the silly to the serious and from the small to the large. One student requested a miniature figurine of the popular Star Wars character Boba Fett; many others have asked for Reggie Redbird heads. The library created a set of large dice labeled on all sides with different music notes for students who wanted to use them when practicing their instruments. Researchers have asked for Möbius strips, microscope adapters, and even a tiny treadmill for a cockroach study.

Also, during the early months of the COVID-19 pandemic, Milner staff organized and led a team of IT units with 3D printers on campus, which included the College of Business and Wonsook Kim College of Fine Arts, to collectively make 900 face shields for the Mclean County Emergency Management Agency.

“Very little of what we do is a life-and-death scenario in IT support, but that was the case when we were printing face shields for McLean County. Those were going to doctors and first responders,” Unsbee said. “Some of these use cases are outside of our wildest fever dreams. It’s always interesting to see what’s going to come through our door next.”

Milner Library’s 3D printing services

Milner Library’s 3D printing service is free for Illinois State students, faculty, and staff. Redbirds simply need to submit a request through the library’s website, which includes links to resources on how to find or create 3D models and how to submit a request to have an object scanned.

Redbirds can submit their own 3D model designs, but it’s more common for them to use publicly available repositories, like Thingiverse. Due to high demand, it takes the library about one to two weeks to fulfill requests.

The wren project led Milner to expand its 3D capabilities.

“(The researchers) were hoping we could create a model for them based on their existing taxidermy model,” Unsbee said. “But we don’t have the staff expertise in-house to create a model from scratch. We got really lucky and found a pre-existing model that met their specifications. But that got us to thinking, ‘How can we somehow bridge that gap?’”

That thought process culminated in the library purchasing a 3D scanner that came online this semester. “You can just place an object on the scanner, and the stereoscopic camera system will automatically create a model as it turns and scans the object,” Unsbee said. “It’s pretty cool.”

It’s also just the latest expansion of a service that is bringing Redbird ideas to 3D.